Changzhou Dewo Motor Co.,Ltd. located in Changzhou city close to Shanghai of China, specialized in acting as produce Hybrid Stepper Motors and its drivers, also agent spindle motor,servo motor, brushless dc motor, related drivers, swith power supply and Accessoriesetc. Our main aim is to be one professional mechatronics supplier and perfect after sale service to our customers.

Our products are widely applied in printing equipment, engraving machine, textile machine, computer external application equipment, medical instruments, stage light equipment, robot, CNC machine and other automatic controlling system.

Our main products include from size NEMA 8, NEMA11, NEMA14, NEMA16, NEMA17, NEMA 23, NEMA24, NEMA 34, NEMA 42, NEMA52 series hybrid stepper motor, and variable sizes linear stepper motor, stepper motor with gear box, stepper motor with brake. And we have products about closed loop systems for nema23, nema24 and nema34 sizes. In addition, we can produce suitable drivers for all the motors. And we always research and develop new products.

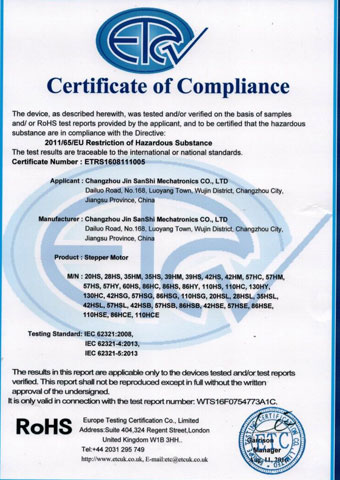

We have pass ISO9001:2008, and have got the certification of CE. On the way of development, the principle of "efficiency is the life, quality is the fundamental. We take the market as guidance, provide high quality products and good service to customers. We also designs and builds products and provides factory-direct support to Original Equipment Manufacturers (OEMs). We are expecting the cooperation with more friends from home and aboard in the near future.

Why do OEM Automation Companies Choose Dewo?

Direct Technical Support

(1)Simulations to optimize and size components for all motion axes

(2)Sensitivity analyses (e.g., how performance varies with changes in load)

(3)Value engineering for mechanics

(4)Recommendations for the best-in-class, third-party components

(5)Direct technical support throughout the life of your machine

Innovative Performance

OEM companies are always looking for ways to differentiate their machines in highly competitive markets. Machine automation is often one of the areas with the most potential to excel. Better performance and reliability are two of the most tangible advantages an-d Dewo has numerous proprietary features that directly address these goals.

Quality and Reliability

Dewo designs and builds products in upstate using single-piece flow manufacturing techniques and comprehensive, automated, quality control. For example, every servo motor undergoes more than 80 in-process quality checks, and gets a 100% full functional test and stress test upon completed assembly. Dewo's focus on quality gives us the confidence to offer a 3+year warranty on all of our servo motors, controls, drives and on.

Honor

|  |

|  |